YTRO-2 with Henrique Miranda about “Porous Alpha”

Henrique Miranda director at Better2earth is here to introduce us to a new patented material called “Porous Alpha” that is produced from waste glass and has diverse applications in Agriculture, water treatment, air treatment, and more!

- Tell us about Better2Earth.

Better2Earth was created in 2019 as a result of a request made by a recycling company that was looking for solutions to utilize surplus waste glass. We started searching for technology that used waste glass and found a Company in Japan that made products from used glass called “Porous Alpha”. B2E now represent the product “Porous Alpha”.

Better2Earth was created in 2019 as a result of a request made by a recycling company that was looking for solutions to utilize surplus waste glass. We started searching for technology that used waste glass and found a Company in Japan that made products from used glass called “Porous Alpha”. B2E now represent the product “Porous Alpha”.

2. About Porous Alpha

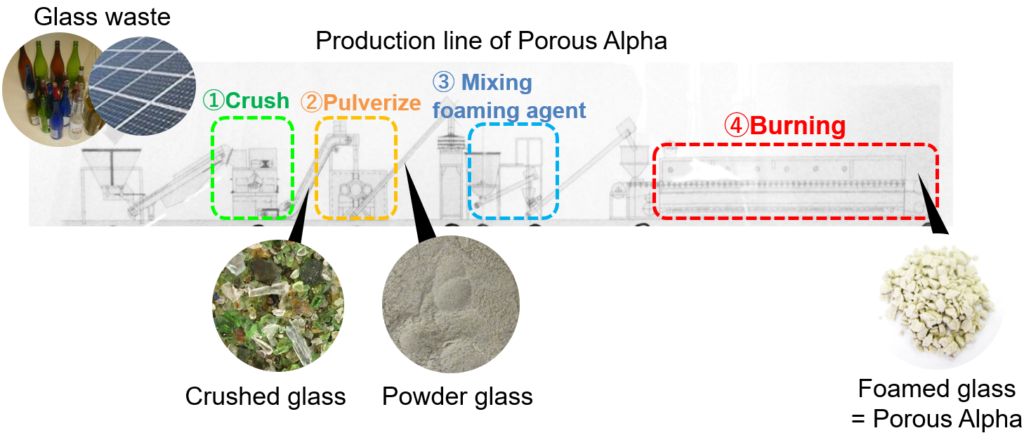

“Porous Alpha” is made from waste glass and used solar panel glass and is a Japanese patented technology. It is basically a combination of recycled glass and calcium carbonate that has a lot of pores and is lightweight. Porous alpha has multiple applications such as a conditioner for soil, water treatment, and air treatment.

3. Was Better2Earth involved with the Japanese company right from the product development?

No, “Porous Alpha” technology has been developed since 2008 and the Company is mainly R&D based. Better2Earth is involved in commercializing the technology across the world and customizing it by developing a co-creation process with the customers.

4. “Porous Alpha” application in Agriculture. (Regenerative / No tilling)

It is an advanced water-saving technology in the agricultural sector. It is applied as a medium for soil and with its excellent water retention capacity, it retains water up to 15% of its total volume. It reduces water usage and fertilizer usage and is compliant with environmental standards. Applications of “Porous Alpha” not only reduce water stress but also gives better crop yield. The product has achieved good results in 5+ countries including Portugal, Morocco, Peru, Spain and South Africa. (Date Palm trees, Olive trees, Cherry trees, tomatoes, and grapes are some of the Trees / Fruits which have been working)

Dosage: Around10% of the tree rooting zone volume and the product’s life span is 15 to 20 years. No requirement to buy it again!!

5. Once the product’s life cycle is complete, is it necessary to separate “Porous Alpha” from the soil? The life cycle is 10-15 years. After lifecycle what is the nature of soil? Do we have to remove it? Is it easy to separate from the soil?

No, “Porous Alpha” is like a cradle-to-cradle concept. Because the product is made from glass and glass is 70% silica which is the composition of most soils.

6. “Porous Alpha” Application in Wastewater treatment?

Phosphorous is one of the main fertilizers in agriculture but is also a problem in wastewater. High phosphorous leads to eutrophication, seen as a (green) colour in rivers and lakes and causes water pollution. “Porous Alpha” with its large specific surface area can be used to recover phosphorus and fluorine through the adsorption process. In addition, the adsorbed phosphorous and fluorine can be recovered in high purity from “Porous Alpha”.

7. “Porous Alpha” Application in Air treatment?

Porous Alpha can be used as a deodorising agent in composting facilities to remove odorous gases. This was the original application/reason why the product was first developed.

8. “Porous Alpha” is made from used glass e.g. solar panels. How is the product quality standardized when glass material’s composition is different each time?

We don’t work with lead-based glass and borosilicate. We use only soda-lime glass and photovoltaic glass can be converted into “Porous Alpha” and we the Japanese Company is the only company in the world that can handle photovoltaic glass and process it (Patented).

9. Is there any other manufacturing unit available in Europe for “Porous Alpha” other than Japan?

No, but Better2Earth aims to have its first manufacturing facility before the end of 2023, and we are also planning to create manufacturing units in other parts of the world. This will also help in creating 15 direct local jobs per plant and additional jobs in creating a structured supply chain mechanism for collecting waste glass including solar panels for the manufacturing unit.

10. How much waste glass has been used so far. Can you give us any rough figures?

There are currently three plants running in Japan manufacturing “Porous Alpha”. One ton of waste glass can be converted into 2.4 m3 of “Porous Alpha”. One plant process 4800 ton/year. There are 3 production plants in Japan.